It is very common to find the area surrounding a cooling tower to be moist or even wet. Water can escape the tower in several ways but most frequently it is the result of excessive drift. So, what is drift? Drift is water that is entrained in the exhaust air leaving the cooling tower. It is in the form of very small droplets which will be dispersed in various areas around the tower depending on exit air velocity and current atmospheric conditions. When walking on or around the cooling tower, if you notice standing water on the fan deck and/or the ground around the cooling tower and it has not been raining, drift is the likely culprit.

Why is drift a bad thing? First and foremost, excessive drift will cause premature failure of the axial flow fans used to induce the airflow through the cooling tower. Due to the rotation of the fan blades, the drift droplets effective “water blast” the leading edges of the blades. Left alone, the resultant etching of the blades will lead to structural failure of the affected blades. Also, drift will cause corrosion on ferrous metal surfaces in and around the tower, create slip, trip and fall hazards and, finally, potential exposure of personnel around the tower to legionella pneumophila.

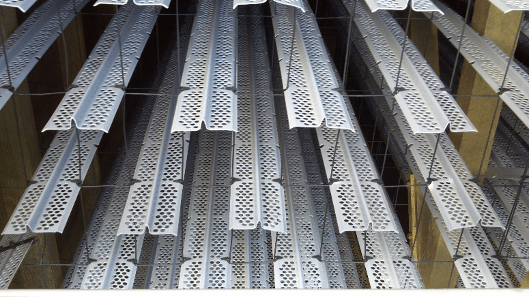

Modern counterflow cooling towers are designed for very low drift rates; typically, 0.0005% of the circulating water flow. Crossflow towers and older counterflow cooling towers were designed for much higher rates; in some cases, 20 times higher. Despite the design drift rate, many towers operate at higher drift rates due to a long list of reasons. They include poor installation practices, poor tower geometry, deterioration of the existing drift eliminator system; or, amazingly, the wrong type of drift eliminator for the tower in question.

When you need to remedy a drift problem, the first step is to select the correct panel based on panel design, operating temperature and of course expected drift rate. Then the installation details and sealing methods need to be considered to be sure the drift eliminators perform as expected. This is a complex process and you likely need experienced help to get it right. Let ATS help you with this to be sure you get the right product and get it installed to minimize the emissions from your cooling tower.