Mechanical Draft

Wood to FRP Conversion

SCOPE OF WORK

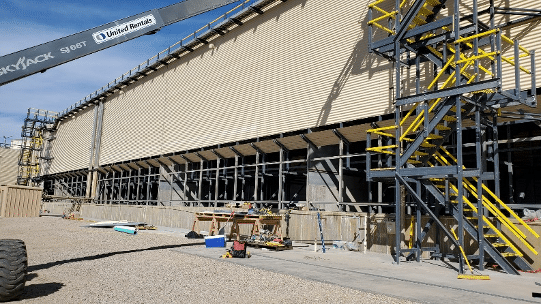

A large Western US power station with multiple generating units required the modernization of a five cell field erected cooling tower serving one of its generating units (275 MWe). The cooling tower structure had previously been partially coverted to a putlruded fiberglass structure (FRP) and this modernization project was to complete that process along with replacement of all remaining wooden components, including the access stairways, with fire retardant FRP materials. Additionally, to gain access to the cooling tower structure, many other internals including heat transfer media (fill), drift eliminators, fire walls, wind walls, and tower casing were all replaced.

PROJECT EXECUTION

The project was executed by an ATS team with extensive experience working in all types of heavy industries, particularly power generation facilities. The team was led by a Project Manager with single point accountability for all aspects of the project and he was in turn supported by the engineering, design, procurement and construction departments of the company.

The extensive scope of work to be performed required detailed design and engineering of all components to be supplied for the project ensuring that form, fit and function were as specified by the client. Complete drawing packages and material lists were then developed and reviewed for constructability by the ATS Project Team including the Field Superintendent that would manage all jobsite activities. Procurement activities then proceeded making certain that all materials were delivered on time and in the right sequence required by the installation activities.

Once field mobilization occurred, ATS staffed the project with an optimal crew required to complete all construction activities in the quickest time using the most effective methods. All activities including demolition and construction were completed in accordance local, state and federal requirements.

RESULTS

• On Time completion, one month ahead of schedule

• Zero Incidents (Safety and Environmental)

• Expected thermal performance