Natural Draft

Component Replacements

PROJECT BACKGROUND

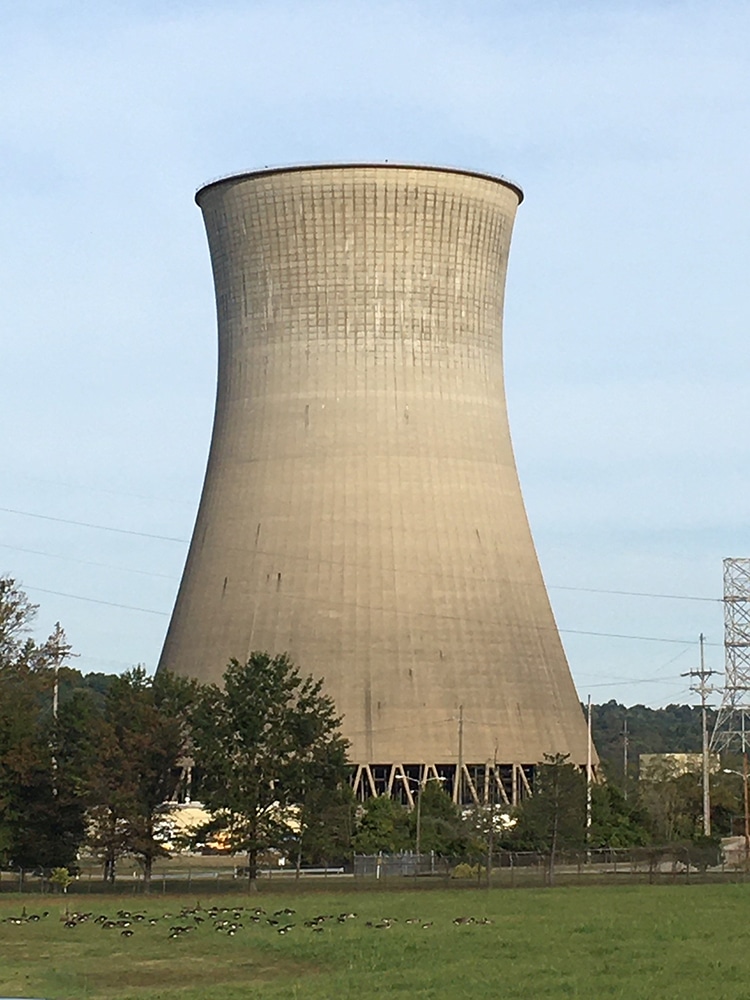

The natural draft cooling tower installed at a large midwestern US coal fired power plant (1,351 MW) required the replacement of severely deteriorated asbestos containing heat transfer media (fill), asbestos containing drift eliminators and asbestos containing hot water distribution piping during a plantwide turbine outage. The outage was planned for 76 days and the work on the cooling tower was considered “Critical Path”.

PROJECT CHALLENGES

The scope of work for the project included abatement and disposal of all asbestos containing materials (fill media, drift eliminators and lateral piping) in the tower. On completion of the removal, new “state of the art” PVC fill, drift eliminators and piping were installed including ATSprayer Patented Yoke Nozzles to insure optimal thermal performance for the tower. The fill and drift eliminator installations also included new pultruded fiberglass supports. Finally, minor structural repairs were performed to various concrete beams.

Working with the Owners Outage Team, ATS and its asbestos abatement partner developed special procedures for removal and disposal of the asbestos containing components as well as the cold water basin sludge that had previously been contaminated with the asbestos containing materials. The safety plan included special worker protection for falling debris, mitigation of fall hazards while working in the cooling tower and worker monitoring to insure PELs were not exceeded. Of course, all of the asbestos abatement and disposal was handled in complete compliance with Federal and State regulations.

Special plans were also required to handle the extremely large volume of materials that would be needed for installation of the new components. Over 100 truckloads of materials were coordinated and delivered on a timely basis to insure the overall planned schedule was achieved.

Once ATS and its asbestos abatement partner mobilized on site, productivity was closely monitored by the ATS Project Manager and Construction Manager to ensure adequate staff was available for the work. ATS, its asbestos abatement partner and the Owners Outage Team all worked closely to successfully manage a team of over 70 workers on the project.

RESULTS

• Early completion allowing the customer to begin power generation sooner than scheduled.

• Zero Incidents (safety or environmental).

• Optimal Thermal Performance as expected.

We offer the most competitive pricing

The close relationships that we have with many component suppliers have enabled us to obtain some of the best discounts available. We then pass on that value and savings to our clients. This means you can buy parts from us at better prices than going direct to the component OEM.