Drift

Eliminators

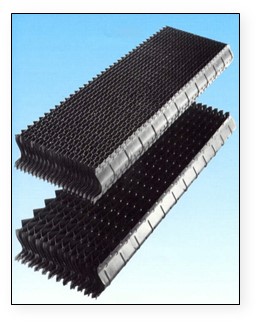

During the normal operation of a wet cooling tower, a small amount of water (in droplet form) is entrained in the exit air stream. This water is referred to as “drift”.

The section of the cooling tower designed to minimize the amount of drift is most commonly known as “drift eliminators” or “mist eliminators”. In any case, drift must be minimized to ensure compliance with plant environmental permits and to reduce or eliminate other problems in and around the cooling tower caused by drift.

Like the heat transfer media in a cooling tower, there are several different configurations available: curved blade styles (single or double skinned), cellular designs and custom designs Materials of construction available including PVC, PP, FRP and stainless teel. Various panel dimensions are also available.

Selection of the correct drift eliminator and installation techniques is critical to minimize the amount of drift leaving the cooling tower. Making the proper selection requires extensive experience and knowledge of the operational principles of each type. Our Regional Technical Managers and Application Engineers have that experience and knowledge. They can help you determine the proper type for your application. Give us a call today and we will show you how.

We offer the most competitive pricing

The close relationships that we have with many component suppliers have enabled us to obtain some of the best discounts available. We then pass on that value and savings to our clients. This means you can buy parts from us at better prices than going direct to the component OEM.